Premium Number 8

Millers Falls No. 8/8C Smoothing Plane

|

Manufactured: |

1929 to 1971 |

| Sole: | Smooth and Corrugated |

| Sole Length: | 8-3/4"(type 1), 9-1/4"(post type 1) |

| Sole Width: | 2-1/4" |

| Iron Width: | 1-3/4” |

| Weight: | 3.0 lbs |

| Bedding Angle: | 45 Degrees |

| Type: | Bailey Design |

| Cross Reference: | Stanley No. 3 / 3C |

| Sargent No. 408 / 408C | |

| Record No. 03 / 03C |

The No. 8 premium smoothing bench plane was produced for over forty-two years across six different types.

Type 1 (1929 to 1935)

There were two distinct changes what can be found while the No. 8 type 1 planes were in production. Sometime in the early 30’s, the frog had a slight redesigned on the face to increase the thickness of the metal around the lever cap screw. One possible reason for this change would be to eliminate stress cracks in the thin wall. This production change to increase the metal around the lever cap screw hole is only seen on the 1-3/4” and 2” frogs.

The patent for the hinged lever cap was approved on September 8, 1931. After the approval, the company set up a stamping press to apply the patent number to the lever cap face. You will find later type 1 lever caps with the patent number stamped above the Millers Falls name and early caps without the patent number applied.

The Millers Falls name is embossed around the knob. This initial release plane does not have a patent number stamp on the lever cap.

The type 1 planes had a cast iron yoke that was painted red.

Type 2 (1936 to 1941)

Millers Falls was expanding their line to companies like Sears to sell this plane and other sizes under the Craftsman and Fulton brand name. A decision was made to standardize the body so that one casting could be used for multiple process lines. As a result, the embossed name and number were removed from the castings. A stamp on the cheek would be used to identify the plane’s model number. Two or more years before the new features on the premium line frog were introduced, these features such as the steel yoke, yoke pin recess and the frog face relief were being used on the Sears planes as well as the Mohawk-Shelburne line. With a passing grade, they were now a part of the type 2 premium line.

At the start of the type 2 production, the No. 8 had a raised tote receiver. Before the type 2 ended, the raised tote receiver was eliminated from the bed. Based on an example from the Dunlap process line, the approximate time this change was implemented is around late 1938.

The rosewood knob/tote with the brass waist nuts, the brass recess depth adjusting nut and the "Since 1868" no touch trademark were all carried over from the type 1 version.

The paint splatter on the knob was an added option that ran about ten cents more per plane.

The type 2 would have the name and number stamped on the left cheek.

The No. 8 had a raised tote receiver through the type 1 years and at the start of the type 2 period. Before the type 2 ended, the raised tote receiver would be eliminated from the casting. This picture shows the early type 2 version to the right and the later type 2 version to the left.

Type 3 (1942 to 1948)

The start of World War 2 limited the use of brass and the import of cocobolo. As a result of the shortages, the company switched to a single steel bolt to secure the stained hardwood knob and tote. Looking at the pictures below, it is easy to identify a type 3 plane with the unique shades in the knob and tote. These shades are a result of the direction of the grain being either long grain or end grain. End grain absorbs more stain for a darker look.

It is easy to identify a type 3 premium bench plane if it has not been altered. The bolts securing the knob and tote and the adjusting nut are clearly not brass. The stain on the beech hardwood knob and tote has a darker end grain look.

Earlier type 3 planes do not have paint around the name on the lever cap. Later type 3 planes have the paint added back around the name.

Type 2 Second Release (1949 to 1952)

Millers Falls returned to the look of the type 2 plane with the rosewood knob and tote secured with brass waist nuts and a double threaded rod. To distinguish the type 2 second release from the original type 2, the trademark on the iron will be stamped “SOLID TOOL STEEL” and the bed will have one or more letter stamps, the casting number and template number. The original type 2 had a “Since 1868” trademark iron and the bed had only the template number.

The type 2 second release will have a rosewood knob and tote and a red frog.

This type will always have the Solid Tool Steel trademark on the iron.

Unlike the original type 2, the second release will have one or more letter stamp on the bed. The casting number will be stamped under the frog adjustment screw on this type.

The type 2 second release will never have a raised tote receiver and the support rib is lower than the original type 2.

Type 4 (1953 to 1965)

It is easy to identify a type 4 plane with black frog and the full brass depth adjusting nut. The wood used on the type 4 has changed from rosewood to the tropical Goncalo Alves. A different shape of the tote is another feature incorporated into the type 4 planes. When comparing this tote to a type 3 version the angle to the bed on the type 4 is 65 degrees compared to the type 3 at 59 degrees. The back along the palm is longer on the type 4 for those people with a larger hand. The horn is the same on both totes. So, for those of us that want more room with less lean on your plane when this tote is for you.

This is an example of a No. 8 type 4 bench plane with the original box.

The tote has a different look in the finish but also the shape. On the left is a type 3 No. 8 tote. On the right is a type 4 No. 8 tote. The type 4 has a longer palm surface, and the angle to the bed is about six degrees greater than the type 3 tote. The horn on both totes are the same.

This is a distinct look with the orange finish, black frog and full depth brass adjusting nut.

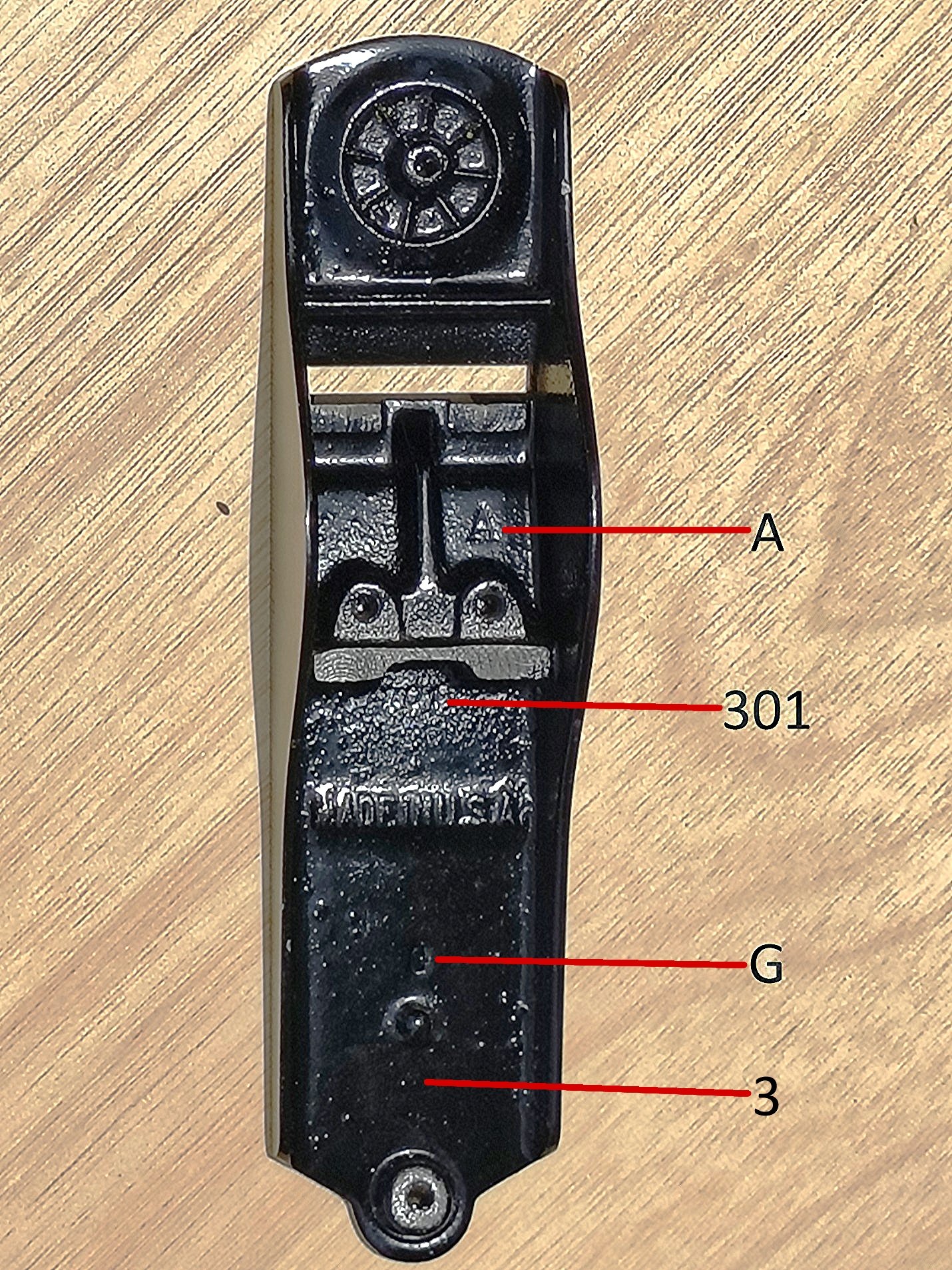

This picture shows the stamps and embossed character you may see on a type 4 body. On the bed under the frog is a capital "A". Behind the frog seat is the casting number "301". At the tote toe area is an upper case "G". You cannot see the last number in the picture under the tote which is a number 4 that could be the template number used to form the body. It is not clear what the letter "A" stands for, but it is also found on the No. 9, No. 90 and the No. 900 during the 50's and 60's.

Type 5 (1966 to 1976)

The features on the No. 8 would follow the type study with all the cutbacks that bled the quality to the point where the word “Premium” was a total misconception. From 1966 to around 1969, the tools were still being cast at the factory in both locations. By the start of 1970, the workers were gone from the Erving location and the foundry was shut down at Greenfield. This is when quality control also left the building.

In 1968, Millers Falls catalog numbers could have the same catalog number for multiple tools, or a catalog number could end with a letter, or even a fraction. At the same time a new technology was introduced to display small items on a card and hang them for display. The company wanted these new carded tools to end with the letter “C”, but there were already tools that ended in “C that were not carded tools. The solution was to rename any tool number that ended in a fraction, a letter or multiple catalog numbers by taking the base number and adding a two digit numeric dash number. By doing this rename, the carded tools in the catalog could now end in a “C”. To use an example, the No. 8 had five tools with the same base number in the catalog: No. 8, 8A, 8B, 8C, and a second No. 8. The new catalog numbers would change these five tools to be references as the No. 8, 8-01, 8-02, 8-03, and 8-04. With this catalog change, the smooth sole No. 8 kept the same model number, but the corrugated version was now listed as the No. 8-03. With this catalog change, all carded tools can now end with a “C”. An example of a carded part in the catalog is the No. 633 nail set bundle. It was changed to the No. 633C.

Remember, the “B” on the type 5 planes was only used on the cheek, it was never in the catalog to identify a part number. The cheek stamp for the corrugated plane changed from 8CB to 8-03-B.

The cheek stamp on this plane tells us it was an earlier type 5 release. The font is the original format. Shortly after the initial release, the font was changed using lower case letters. This plane has all upper case letters.

The type 5 had a nickel depth adjusting nut on a black frog. The frog adjuster screw was eliminated on all type 5 planes.

An example of a type 5 No. 8B with the original box.

This picture shows the two different cheek stamps for the No. 8 type 5 corrugated plane. The top picture is the stamp applied before October 1968. The bottom picture shows the stamp when the catalog number was changed from 8C to 8-03 after October 1968. The "B" is only on the cheek, not in the catalog.