No. 16 Full Adjustment Block Plane

|

No. 16 Manufactured: |

1929 to 1965 |

| No. 16C Manufactured: | 1965 to 1971 |

| Sole Length: | 6-1/4” |

| Iron Width: | 1-5/8” |

| Weight: | 1.45 lbs |

| Bedding Angle: | 20 Degrees |

| Adjustments: | Fully Adjustable |

| Lever Cap Type: | Cam Lock |

| Casting Number Body: | 497 |

| Casting Number Cap: | 344 |

| Cross Reference: | Stanley No. 9-1/2 |

No. 16

The No. 16 was probably the most popular block plane Millers Falls produced based on the number of planes you can find today. This plane has an adjustable mouth, a depth adjusting nut and a lateral adjustment lever. The front knob and the adjustment nut are usually nickel plated, but for a short time in the thirties these two are seen with a brass finish. The eccentric lever will have the end bent down.

Type 1 configuration – 1929 - 1935

Millers Falls name cast in front of the finger rest knob.

The iron landing has a full surface with no recess.

After the initial release, the name and number are stamped on the cheek.

Lateral adjustment lever has the metal folded to engage the iron slot.

Cam lock lever cap is painted red (1929-1932), later, the lever cap is painted black (1933-1965)

“Since 1868” iron trademark (see irons for more details)

Type 2 configuration starting 1936 to 1965

Millers Falls embossed name is removed from the bed.

Iron landing has a recessed area.

Lateral adjustment lever has a solid disk to engage the iron slot.

1949 - Iron trademark was changed to include the words “Solid Tool Steel”.

Type 3 configuration starting 1966 to 1971

The frog is redesigned from the depth adjusting nut to a depth adjusting screw.

The depth adjustment screw knob has a straight pattern knurling.

The iron is redesigned with three oval holes.

No trademark is present on the iron.

The number 16 on the cheek will have a “C” added.

The No. 16 with an adjustable mouth, cam lever cap, finger grip on the cheek, lateral adjustment lever and a depth adjusting nut.

Millers Falls used the classic standard mechanism to incorporate the iron adjustment combined with a lateral adjustment lever.

Two different eccentric levers were produced by Millers Falls, the 1-3/8 with the end bent up and the 1-5/8 with the end bent down. The No. 16 requires an eccentric lever with the end bent down.

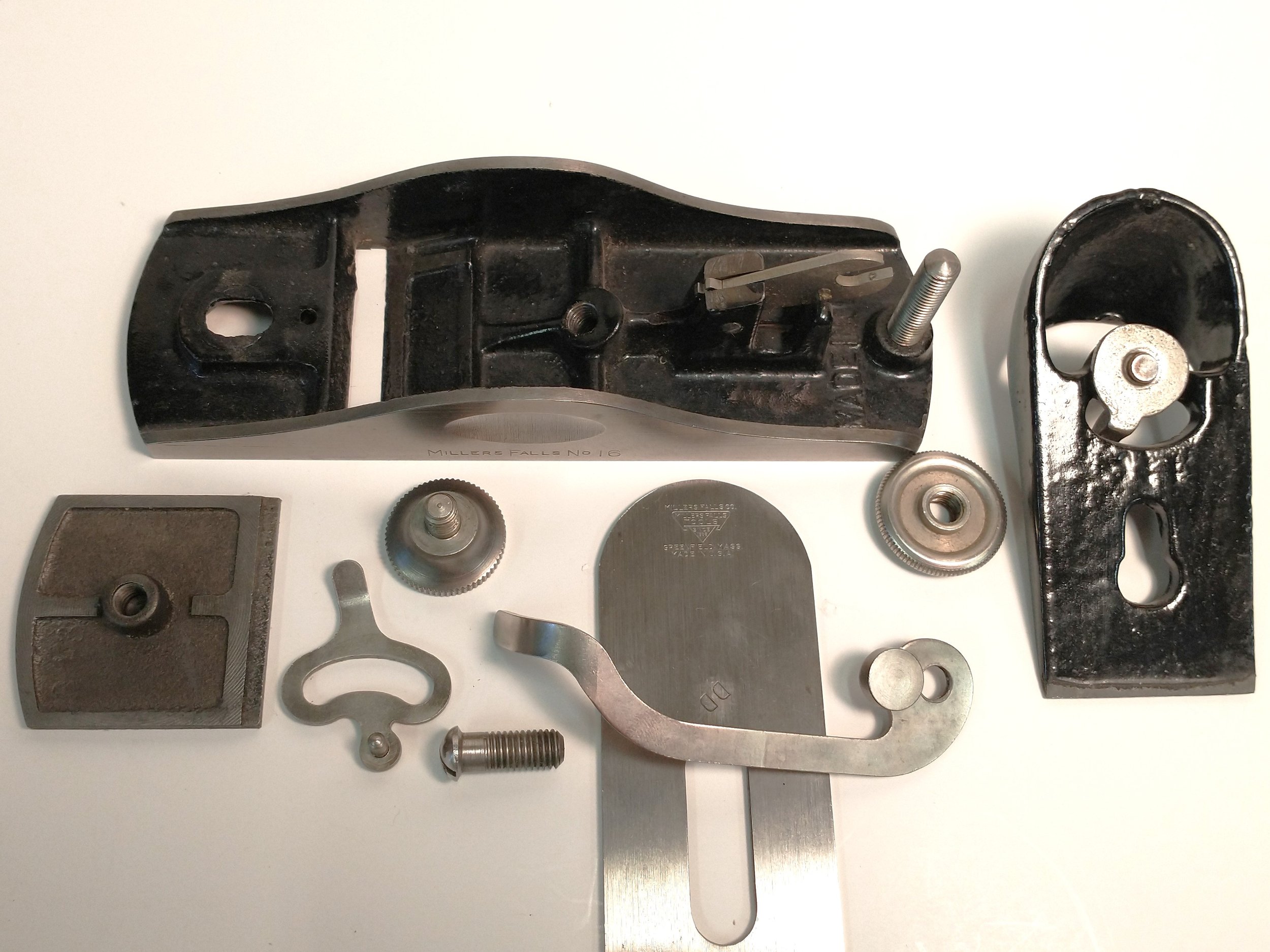

Complete breakdown of the No. 16. Not counting the pins, this plane has twelve parts, four cast iron and eight steel parts.

The top plane shows an initial configuration with Name cast in the bed, solid iron landing, folded lateral adjustment lever. The bottom plane shows the second configuration with no name cast in the bed, recessed iron landing, disk lateral adjustment lever. Both versions have the name and number stamped on the cheek. The camera lens makes the top plane look smaller. The are the same size.

No. 16C and No. 16CG

In the mid 60’s, Millers Falls made the decision to consolidate the process and eliminate some of the factory machinery to manufacture planes. At the time this decision was made to consolidate the process line, the company was producing six adjustable block planes. Of these six, five were using a depth adjusting screw mechanism which would become the standard for adjusting an iron.

The No. 16 was the only block plane left with a depth adjusting nut to adjust the iron. This type of adjustment would not support the new configuration so the casting was changed to the depth adjusting screw configuration. The No. 16 was also the only block plane left that had a lateral adjustment lever. This also had to be redesigned for the lever to go under the screw knob. The range of movement on the redesign was very limited because of the wider frog needed for the screw knob adjustment.

You will find this new configuration under two different model numbers: the No. 16C and the No. 16CG. Both model numbers are basically the same except for the casting layout. The 16C has the “Made In USA” on one line while the 16CB will have it on either one or two lines.

In the mid-sixties when all existing planes were redesigned, the No. 16 was the only plane to have a “C” added to the stamp on the cheek. All the other planes had a “B” added to the cheek. The “B” and “C” were never reflected in the catalog, only on the plane’s cheek. In 1967 if you looked for a No. 16C in the current catalog or price list, you would only find a No. 16.

Millers Falls also added a “G” to the cheek stamp model number after the mid-sixties. The popular belief is the “G” referred to a government contract plane. You will find more “16CG” planes on the market than “16C” versions.

No 16CG

This is the configuration of the No. 16C and No 16CG

This picture shows the original style plane with the depth adjusting nut on the bottom and the new depth adjusting screw on the top. These two planes are completely different but Millers Falls decided that the new style would have the same 497 casting number as the original. On the two-inch bench plane frog, the company changed the casting numbers twice with no changes to the design or configuration of the frog. Here there is a significant change, and the number stays the same. I give up trying to figure this one out.

All three of these bodies are No. 16CG. The planes on the left and center have Made In USA on two lines. The plane on the right, Made In USA is on one line. The plane on the left has a bridge between the frog and lever cap screw. The other two do not have this bridge. The foundry at Millers Falls was shut down in 1969 and all castings were outsourced. The body on the right was probably made in house and the two on the left were outsourced.